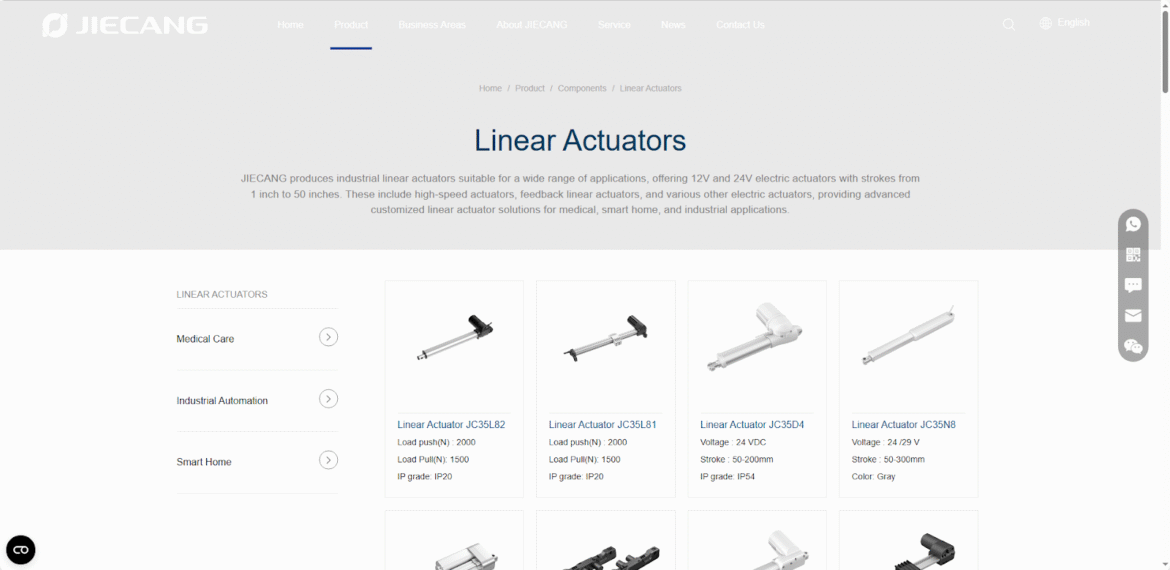

Linear actuators, as indispensable key components in modern industrial, medical, smart furniture, and automation systems, are gradually replacing traditional hydraulic or pneumatic drive solutions due to their high precision, low noise, and flexible adjustment capabilities. Whether in precision robot bases, operating table lifting platforms, height-adjustable desks, or modular smart home furniture, linear actuators provide stable and controllable linear motion, making equipment operation more efficient, safe, and comfortable. This article will delve into the design concepts and application practices of linear actuators from aspects such as system positioning and engineering value, core structure and working principle, engineering applications, control optimization, selection guidelines, and technological trends, providing professional reference for engineers, designers, and smart device developers.

1. System Positioning and Engineering Value

Linear actuators are indispensable “lifting and movement engines” in modern industrial, medical equipment, and smart home systems, providing smooth and controllable linear motion for robot bases, operating tables, electric desktops, or height-adjustable furniture. Compared to traditional hydraulic or pneumatic solutions, linear actuators offer significant advantages in position control accuracy, response speed, energy efficiency, and ease of maintenance: they achieve high-precision, high-frequency repetitive motion without the need for hydraulic oil or complex piping.

In engineering design, selecting a suitable linear actuator requires comprehensive consideration of several key factors, including load weight and type, motion speed and dynamic response accuracy, repetitive motion stability, and noise control requirements. Properly matching these indicators ensures the actuator delivers maximum value within the system, providing a reliable, efficient, and smooth linear motion solution for the equipment, thereby improving overall performance and user experience.

2. Innovative Design and System Integration

Linear actuators are not merely “push-pull devices”; they can achieve highly precise and smooth motion thanks to control systems and intelligent adjustments. Modern linear actuators are typically equipped with closed-loop control and position feedback systems, such as encoders, Hall effect sensors, or torque feedback, which provide real-time information on the actuator’s position and force, ensuring accurate lifting and lowering to preset heights.

When multiple actuators are used in a system, synchronization algorithms are also required to coordinate their movements. For example, in multi-column lifting platforms or double-leg lifting desks, the stroke and speed of each actuator must be fine-tuned to ensure smooth movement of the entire system, preventing tilting or asynchrony.

To enhance the user experience, the motion of linear actuators is also optimized for smoothness: acceleration and deceleration curves are designed so that starting and stopping feel like a “gentle glide,” rather than a sudden impact.

In terms of intelligence, modern actuators can connect to various interfaces: PLCs, embedded control systems, and even support IoT communication and remote debugging. This allows for control via computer or mobile phone, as well as automated adjustment, remote monitoring, and upgrades, making linear actuators more flexible and intelligent in industrial, office, and home environments.

3. Engineering Applications and Practical Challenges

Linear actuators are widely used in various engineering scenarios, enabling equipment to move up and down or adjust its height. For example, in industrial automation, they can be used on robot bases or assembly lines, allowing workbenches to rise and fall according to task requirements, improving production efficiency. In medical equipment, actuators enable the smooth raising and lowering of operating tables, nursing beds, or radiology support platforms, facilitating medical operations and enhancing patient comfort.

In the office and commercial sectors, actuators support the height adjustment of motorized lecterns, height-adjustable desks, and multimedia displays, allowing users to change angles or positions as needed. In smart homes, they can drive height-adjustable TV cabinets, kitchen countertops, or modular furniture, providing convenience and flexibility for home life.

Of course, practical applications also present some challenges. Uneven loads can introduce mechanical stress; environmental humidity and temperature can affect motor or sensor performance; low-noise designs are necessary for applications with high noise requirements; and maintenance and installation require special consideration when space is limited. Understanding these factors helps in making more accurate and safer selections and uses.

Conclusion

Linear actuators are not merely simple mechanical drive components, but core motion execution devices in modern intelligent systems. With their precise positioning capabilities, smooth motion characteristics, and integrable intelligent control interfaces, they play a crucial role in industrial automation, medical equipment, office systems, and smart homes. With the development of high-power-density motors, low-noise designs, multi-actuator synchronous control, and IoT integration, future linear actuators will be lighter, more efficient, and more intelligent, capable of meeting more complex and precise motion control needs, and driving the automation and intelligent upgrades of various industries.

Linear Actuator FAQ

1.Can linear actuators replace traditional mechanical guide rail systems?

Yes. In many precision applications, linear actuators provide controllable linear motion driven by motors. This not only reduces manual adjustments but also enables closed-loop control and automatic synchronization, making them suitable for scenarios requiring repetitive and precise movements in automated production lines, experimental equipment, or smart furniture.

2.How to evaluate the load capacity of a linear actuator?

Load capacity depends not only on the maximum load capacity but also on dynamic loads and lateral forces. Uneven load distribution or impact forces can cause premature wear or failure of the actuator. Therefore, when selecting a linear actuator, it is essential to calculate peak and continuous loads based on the actual working environment and to allow for safety margins.

3.How to ensure synchronized movement in a multi-actuator system?

In a multi-actuator system, ensuring synchronized movement of all actuators is crucial; otherwise, tilting or jamming may occur. This is typically achieved through electronic closed-loop control, where each actuator coordinates its movements via feedback signals from position sensors, resulting in precise synchronization. Another method is mechanical coupling or synchronizing rods, which physically connect and ensure consistent movement of all actuators. Furthermore, intelligent algorithms can dynamically adjust the speed and start-up sequence of each actuator, fine-tuning according to load distribution to further improve synchronization accuracy and system stability.

4.What factors affect the lifespan of a linear actuator?

The lifespan of a linear actuator depends primarily on several factors. First, usage frequency and load size directly affect mechanical wear and motor lifespan. The working environment is also critical; high temperature, high humidity, dust, or corrosive gases can accelerate aging. Second, the smoothness of operation is equally important; frequent sudden stops or impacts increase wear. Finally, motor type, transmission system, and lubrication condition also affect lifespan. Regular inspection and maintenance can significantly extend the service life of linear actuators, ensuring long-term stable operation of the equipment.