RF (Radio Frequency) connectors are essential components in electronic systems that transmit high-frequency signals. They are used in a wide range of applications, including telecommunications, aerospace, automotive electronics, medical devices, and industrial systems. The primary purpose of an RF connector is to provide a secure and reliable connection that maintains signal integrity and minimizes loss. Selecting the right connector for high-frequency signals is critical, as even minor mismatches or quality issues can lead to signal degradation, interference, or system failures.

The Best RF Connectors for high-frequency applications are designed to deliver optimal electrical performance, mechanical durability, and environmental resilience. They are engineered to minimize insertion loss, maintain impedance matching, and provide consistent performance across a wide frequency range. For those looking to implement reliable high-frequency connections, a trusted Best RF Connectors provider offers a range of high-performance solutions suitable for demanding applications and precise signal transmission requirements.

Understanding Frequency Requirements

One of the first steps in choosing an RF connector is understanding the frequency requirements of your application. High-frequency signals, often above 1 GHz, are more susceptible to reflection, signal loss, and interference. Connectors must be specifically designed to operate at the required frequency range while maintaining proper impedance. A mismatch in impedance can lead to signal reflections, reduced transmission efficiency, and increased return loss. Engineers should carefully review connector specifications, including frequency range, insertion loss, and VSWR (Voltage Standing Wave Ratio), to ensure compatibility with high-frequency systems.

Impedance Matching

Impedance matching is critical in high-frequency RF systems. The connector’s impedance, typically 50 or 75 ohms, must match the impedance of the cable and the system components. Even small deviations can cause reflections, signal distortion, and reduced performance. High-quality connectors are manufactured with precise tolerances to maintain impedance consistency, which is especially important in applications such as 5G networks, radar systems, and satellite communications. Choosing connectors with accurate impedance specifications ensures reliable signal transmission and minimal performance loss.

Material Selection and Conductivity

Materials play a significant role in the performance of high-frequency RF connectors. Contacts are commonly made from beryllium copper, brass, or stainless steel, often plated with gold, silver, or nickel to improve conductivity and prevent corrosion. Plating enhances the signal transfer while maintaining durability over repeated mating cycles. Insulators and connector housings are typically made from high-performance polymers or ceramics that provide thermal stability, electrical insulation, and mechanical resilience. Selecting connectors with premium materials ensures long-term reliability and minimal signal degradation, even in high-frequency applications.

Mechanical Durability

High-frequency applications often require connectors that can withstand frequent mating cycles, vibration, and mechanical stress without compromising performance. Connectors used in aerospace, military, automotive, or industrial systems must maintain electrical stability under harsh conditions. Features such as ruggedized housing, reinforced contacts, and vibration-resistant designs contribute to mechanical durability. By prioritizing durability, engineers ensure that high-frequency connectors maintain consistent performance throughout their operational life.

Environmental Considerations

High-frequency connectors may be exposed to challenging environmental conditions, including extreme temperatures, humidity, dust, and corrosive substances. The best RF connectors are designed with environmental resistance in mind, including sealing for moisture protection, corrosion-resistant plating, and heat-stable materials. Environmental resilience is essential for applications in outdoor communication systems, industrial automation, and military operations where reliability cannot be compromised.

Connector Type and Compatibility

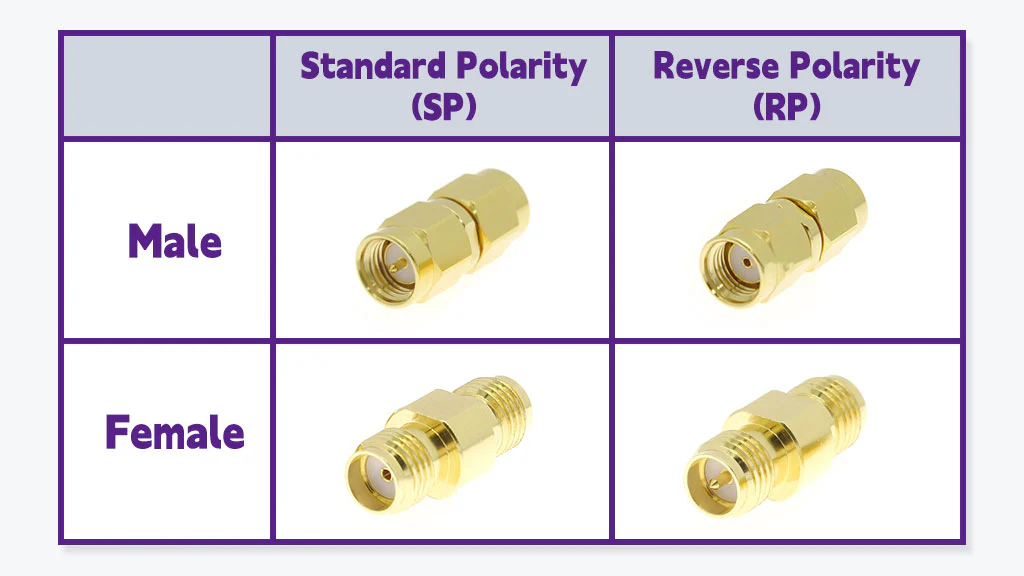

Different high-frequency applications may require specific connector types, such as SMA, N-type, BNC, or TNC connectors. Each type has unique characteristics, including size, frequency range, and mating design. Selecting the correct connector type ensures mechanical compatibility, optimal signal transmission, and ease of installation. Additionally, ensuring that the connector is compatible with existing cables, devices, and equipment reduces the risk of installation errors and performance issues.

Conclusion

Choosing the best RF connector for high-frequency signals requires careful consideration of frequency requirements, impedance matching, material quality, mechanical durability, environmental resistance, and connector type. High-quality connectors maintain signal integrity, minimize loss, and provide reliable performance even under challenging conditions.

Partnering with a reputable supplier of Best RF Connectors ensures access to high-performance, durable, and precise connectors that meet the demands of high-frequency applications. By prioritizing these factors, engineers and technicians can optimize system performance, reduce maintenance costs, and ensure long-term reliability for critical electronic and communication systems.