Every breath we take indoors is processed by advanced equipment meant to protect our health and comfort. The unsung heroes of indoor air quality of large complexes of residential buildings, hospitals, schools, and business buildings are ahu unit or air handling units. These are spectacular systems that are used to filter, cool, heat, and circulate air throughout entire buildings 24 hours a day. The contribution that these units make to our comfort in our day to day life cannot be disputed although the vast majority of us never get to view them in the rooftops or the mechanical rooms. Understanding the principle of operation and what makes AHUs efficient would allow us to admire the dynamic nature of engineering that keeps our interior rooms comfortable and healthy in all seasons.

- Breaking Down the Basics: What an AHU Actually Does

An air handling unit serves as a central process station in the generation of air by combining multiple tasks to a single and unified system. They absorb the external air, mix it with cycled inside air and then warm up the mixture to meet pre-established humidity and temperature requirements. The air moves through filters where it gets dust, pollen and other impurities removed and then moves through heating or cooling coils within the metal cabinet. The pressure required to force this cleaned air through a vast system of ducts that reach every occupied location is produced by fans. Refreshing indoor air several times an hour, the entire procedure is ongoing. In order to ensure optimal performance and minimize energy waste, modern AHUs feature complex controls that modify operation based on occupancy, weather, and indoor air quality sensors.

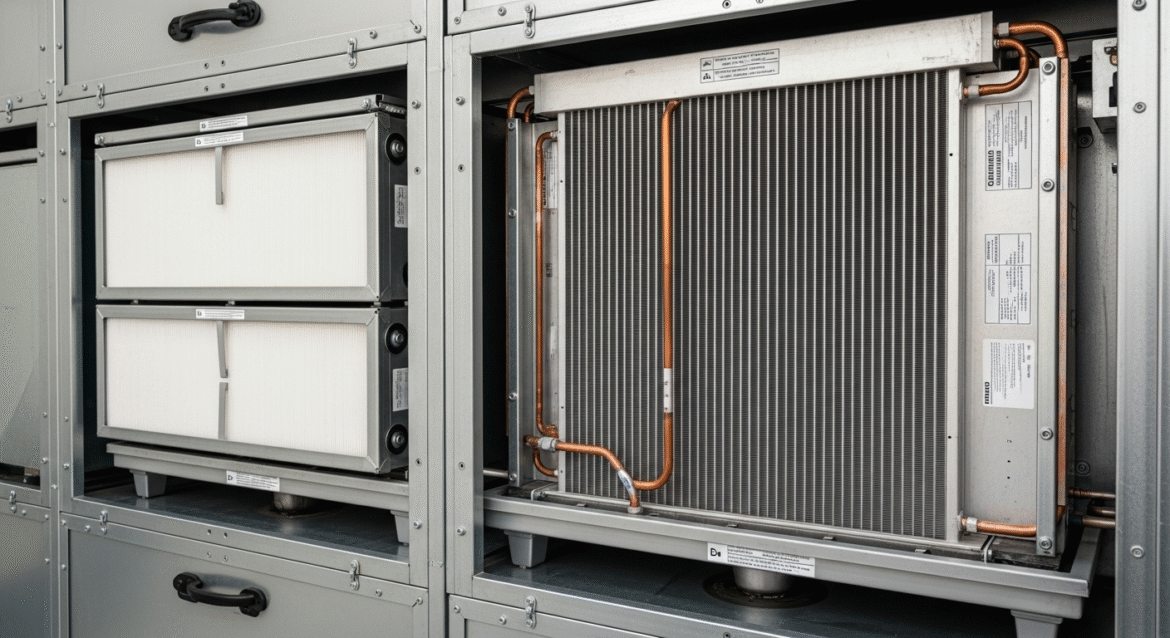

- Component Breakdown: Understanding the Internal Machinery

Every AHU cabinet holds a carefully designed collection of parts that is complete. The filter part containing several filter stages where the particles of various sizes are captured often appears in the way of airflow first. The refrigerant, chilled water, or hot water pipes contained in the heating and cooling coils consume a lot of space outside the filters. The fan section contains large axial or centrifugal fans capable of moving thousands of cubic feet of air per minute. Dampers are used to control the combination of recirculated return air and fresh outdoor air through moving gates. Cooling operations give in to drainage pans to collect condensation, and the humidification equipment supplies moisture on dry days. Access panels allow technicians to work on the components effectively and safely, whereas sound attenuators help to reduce the level of noise.

- Fresh Air Requirements: Why Ventilation Matters

AHUs are involved in managing the crucial process of the constant supply of outdoor air to the building to provide hygienic internal environments. Lack of fresh air leads to an increase in carbon dioxide levels, accumulation of odors, and a rapid drop in the level of comfort of occupants. To make sure that sufficient oxygen supply and pollutant dilution is provided, the building standards pose minimum ventilation rates depending on the type and density of occupancy. To meet these requirements and take into account the concerns of energy efficiency, external air intake has been constantly controlled and adjusted by AHUs. Adding unconditioned outdoor air during severe weather considerably raises heating or cooling loads. By transferring heat between entering and leaving airstreams, energy recovery devices aid in overcoming this difficulty. One of the most crucial components of AHU functioning is the meticulous control of fresh air intake, which has a direct impact on operating expenses and occupant health.

- Temperature Control: Mastering Climate Precision

Large structures require precise control and sensitive equipment to maintain constant temperatures. Heating and cooling coils in AHUs quickly change the air’s temperature as it moves through the unit to accomplish this. While chilled water coils are connected to refrigeration equipment that generates cold water, hot water coils are connected to boilers or heat pumps. Some systems use direct expansion coils, which do away with the requirement for separate chilled water systems by allowing refrigerant to evaporate inside the AHU. Coil valve settings are adjusted to meet demand by control systems that get continual data from temperature sensors positioned around the building. Modern controls automatically switch between heating along with cooling modes in response to seasonal fluctuations. Maintaining temperature within specific ranges greatly enhances occupant comfort as well as productivity.

- Filter Technology: Protecting Air Quality Standards

One essential function that has a direct impact on comfort, health, and system lifetime is air filtration. Typically, AHUs use several filter stages, each of which targets a distinct set of pollutants and particle sizes. Pre-filters prolong the life of more costly downstream filters by capturing bigger particles like dust and lint. Pollen, mold spores, and some bacteria are among the tiny particles that are eliminated by medium-efficiency filters. When necessary, high-efficiency particulate air filters are remarkably effective at capturing small particles. Because denser filters require more fan energy to drive air through them, choosing a filter requires balancing pressure drop and running expenses against air quality requirements. Frequent filter replacement keeps performance at its best and avoids polluted accumulation that could lower air quality. Filters need to be handled and disposed of carefully in specialized settings like labs or hospitals.

- Balancing Comfort along with Efficiency

Since most commercial buildings’ AHUs are among the biggest energy users, efficiency upgrades are financially appealing. The majority of AHU energy consumption is usually attributed to fan motors, which run constantly to keep airflow going during occupied hours. Variable frequency drives provide significant energy savings by enabling fan speeds to change in response to real demand rather than operating at maximum capacity all the time. Maintaining motors and fans properly guarantees that they run as efficiently as possible without wasting energy overcoming needless resistance. When temperatures outdoors permit free cooling, economizer controls increase fresh air intake to capitalize on favorable external conditions. Heat recovery systems absorb energy from exhaust air that would otherwise be squandered. Every efficiency boost lowers operating expenses and advances environmental sustainability objectives, which are having a bigger impact on decisions about building design and operation.

Conclusion

Air handling units are important in the modern building ventilation and climate control systems. The control of the temperature, the humidity, the filtration, and air circulation is all combined into one, well-designed system that makes the interiors comfortable and healthy. Having a good grasp of ahu air operation, maintenance needs, and growing technologies, building managers can make the most of performance, minimise costs and support the wellness of occupants efficiently.