Water soluble film packaging machines have transformed industrial packaging by providing efficient, safe, and environmentally friendly solutions for single-dose and pre-measured products. These machines use water soluble films to package powders, liquids, gels, and other products that dissolve completely in water. Industrial sectors such as detergents, cleaning chemicals, pharmaceuticals, and healthcare increasingly rely on this technology for its precision, hygiene, and convenience. Understanding how these machines operate is essential for manufacturers seeking to improve productivity and maintain product quality.

Components of a Water Soluble Film Packaging Machine

A water soluble film packaging machine is a sophisticated system composed of several integrated components designed to handle delicate films while ensuring accurate dosing and sealing. The key components include the film feeding system, forming mechanism, filling unit, sealing and cutting mechanism, and control systems.

The film feeding system ensures the continuous and controlled supply of water soluble film. It usually consists of rollers and tension control devices that prevent wrinkling or tearing during production. The forming mechanism shapes the film into pouches, sachets, or pods suitable for the product type. The filling unit then deposits a precise amount of powder, liquid, or gel into each formed package. Finally, the sealing and cutting system creates secure, leak-proof seals and separates individual packages. Control systems, often integrated with sensors and software, monitor the entire process to ensure consistency and efficiency.

The Packaging Process

The operation of a water soluble film packaging machine follows a sequence of steps designed to maintain precision and protect the sensitive film material. First, the film roll is unwound and fed into the forming unit. The machine forms the film into the desired shape, typically a pouch or capsule, using molds or thermoforming techniques. This forming process ensures that each package has uniform size and structure.

Next, the filling unit dispenses the product into the formed film. The type of filling system depends on the product being packaged. Liquids are commonly handled by volumetric pumps or flow meters, powders may use auger or screw fillers, and gels can be filled with piston or positive displacement pumps. The machine ensures accurate dosing for each package, which is critical for industrial applications where consistency and safety are paramount.

In the middle of this process, a high-quality Water Soluble Film Packaging Machine integrates automated sealing and cutting systems. Heat sealing or ultrasonic sealing technology creates secure seals that prevent leaks and maintain package integrity. Cutting units then separate individual units while preserving the accuracy and cleanliness of each package. The machine’s sensors and control systems constantly monitor fill volume, sealing temperature, and film tension to maintain consistent quality throughout the production run.

Applications in Industrial Packaging

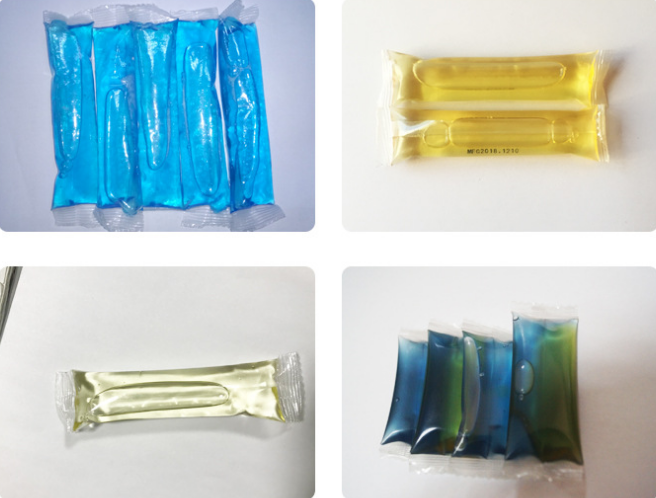

Water soluble film packaging machines are widely used in industrial sectors that require precise and safe packaging solutions. In the detergent and cleaning industry, these machines produce single-dose laundry pods, dishwasher capsules, and chemical packets. Industrial cleaning operations benefit from pre-measured packs that reduce handling risks and ensure accurate application.

Pharmaceutical and healthcare industries also utilize these machines to package powders, gels, and liquids in sterile, single-dose formats. Hospitals, clinics, and laboratories rely on the accuracy and hygiene provided by water soluble film packaging machines to maintain patient safety and regulatory compliance. These machines are capable of high-speed operation, producing thousands of units per hour while maintaining precision and minimizing waste.

Advantages for Industrial Packaging

The use of water soluble film packaging machines in industrial settings provides several advantages. First, they improve efficiency by automating repetitive tasks, reducing manual labor, and maintaining high-speed production. This allows manufacturers to scale operations without compromising product quality or safety.

Second, they enhance consistency and accuracy. Automated dosing systems, temperature-controlled sealing, and precision cutting ensure uniform package size, weight, and content. This is particularly important for industrial products that require strict adherence to standards and regulations.

Third, water soluble film packaging machines improve hygiene. Minimal human contact during packaging reduces the risk of contamination, while enclosed and easy-to-clean components maintain sterile conditions for sensitive products. Finally, these machines support sustainability goals. Water soluble films dissolve completely in water, reducing packaging waste and contributing to eco-friendly operations.

Maintenance and Operational Considerations

To maintain optimal performance, water soluble film packaging machines require regular preventive maintenance. This includes cleaning rollers, molds, and sealing jaws, checking tension and alignment, and calibrating filling systems. Monitoring environmental factors such as humidity and temperature is also critical, as water soluble films are highly sensitive to moisture. Proper operator training ensures that machines are used correctly and maintained efficiently, minimizing downtime and extending the lifespan of the equipment.

Conclusion

Water soluble film packaging machines are essential for industrial packaging operations that prioritize efficiency, consistency, hygiene, and sustainability. By automating the processes of film feeding, forming, filling, sealing, and cutting, these machines produce precise, high-quality packages suitable for detergents, chemicals, pharmaceuticals, and healthcare products. With their ability to handle high-speed production while maintaining accuracy, water soluble film packaging machines offer manufacturers a reliable and eco-friendly solution for modern industrial packaging challenges. Proper maintenance, operator training, and environmental control further enhance machine performance and ensure consistent, safe, and high-quality packaging.