Investing in a Swiss lathe machine represents a significant decision for any precision manufacturing operation. These machines are designed to produce small, complex components with tight tolerances, making them critical for industries such as medical, aerospace, and electronics. Understanding cost factors before purchase ensures that the investment aligns with production needs, efficiency goals, and long-term operational budgets.

Initial Purchase Price

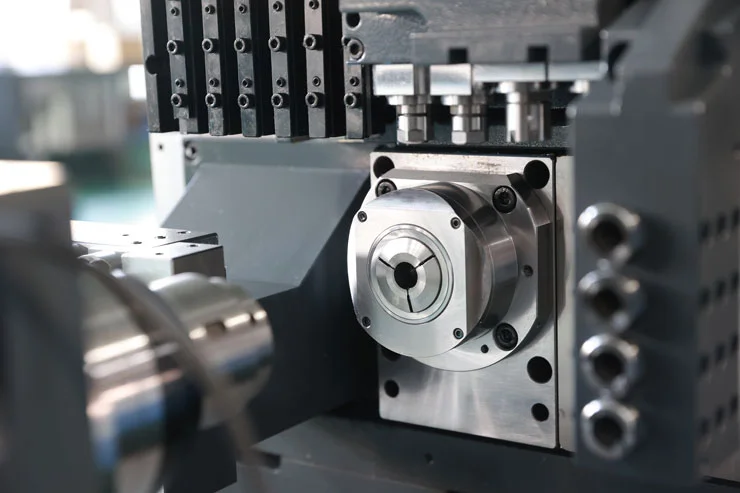

The upfront cost of a Swiss lathe machine varies depending on its size, features, and level of automation. Basic fixed-headstock models may be more affordable, while advanced multi-axis CNC machines with live tooling and automatic bar feeders tend to command higher prices. The purchase price is influenced by spindle speed, tool capacity, software capabilities, and the quality of construction. Evaluating the total cost against expected production output helps determine the right balance between upfront investment and operational efficiency.

Operational Costs

Beyond the initial price, operational costs play a key role in evaluating the financial feasibility of a Swiss lathe machine. Energy consumption, coolant and lubrication requirements, tooling expenses, and routine maintenance should all be factored in. Machines with higher automation may reduce labor costs but could require more specialized servicing. Considering the long-term operational costs ensures that the machine remains cost-effective throughout its service life.

Return on Investment and Productivity

Maximizing productivity and minimizing downtime are essential for achieving a positive return on investment. A Swiss lathe machine that performs multi-axis operations, maintains high repeatability, and supports continuous production can significantly reduce cycle times and scrap rates. Selecting a model with advanced features like live tooling, error detection, and automated material handling can improve throughput, ultimately offsetting the higher initial cost. For example, choosing a swiss lathe machine with integrated automation can enhance efficiency and reduce labor dependency, providing substantial long-term savings.

Material and Tooling Considerations

The types of materials and tooling requirements also influence the overall cost. Machines capable of handling harder metals such as stainless steel or titanium may require specialized cutting tools and higher spindle rigidity. Tool wear, replacement frequency, and material waste contribute to ongoing expenses. Selecting a machine compatible with the intended workpiece materials while maintaining precision can optimize both performance and cost-efficiency.

Maintenance and Servicing

Maintenance is a critical aspect of cost management for Swiss lathe machines. CNC models with multiple axes and live tooling require regular inspection, lubrication, and calibration. Factoring in the cost of maintenance contracts, spare parts, and technician support is essential to avoid unexpected downtime. Machines with accessible components and automated diagnostic features often reduce servicing time and associated costs, ensuring consistent production with minimal disruption.

Training and Operator Efficiency

Operator training is another consideration that indirectly affects the total cost. Advanced machines may require specialized programming knowledge, familiarity with CNC interfaces, and understanding of multi-axis operations. Well-trained operators improve efficiency, reduce errors, and minimize material waste. Investing in training may increase initial expenses but contributes to higher productivity and lower operational risks over time.

Space and Infrastructure Requirements

The physical footprint and infrastructure requirements of a Swiss lathe machine impact overall cost. Machines with larger sizes, cooling systems, and automation components may require modifications to the workshop layout or additional utilities such as power supply and compressed air. Ensuring that the workspace can accommodate the machine without compromising workflow helps avoid costly adjustments after purchase.

Depreciation and Resale Value

Considering depreciation and potential resale value is also important. High-quality Swiss lathe machines from reputable manufacturers tend to retain value better over time. Evaluating the expected service life and possible resale options can influence the total cost of ownership. Investing in machines with durable construction and reliable components helps protect long-term value while ensuring operational performance.

Conclusion

Purchasing a Swiss lathe machine requires careful analysis of initial investment, operational costs, productivity gains, material and tooling requirements, maintenance, training, infrastructure, and long-term value. By evaluating these factors holistically, manufacturers can select a machine that balances cost with performance, reliability, and efficiency. Thoughtful decision-making ensures that the investment supports consistent production quality and delivers measurable returns over the life of the equipment.