Automation has become a defining factor in modern manufacturing, significantly transforming the operations of press machine factories. By integrating automated systems into production processes, factories can achieve higher precision, improved efficiency, and consistent product quality. Automation reduces human error, accelerates production cycles, and enhances safety for operators working with high-force machinery. Understanding the role of automation in press machine factories is essential for manufacturers looking to stay competitive in today’s industrial landscape.

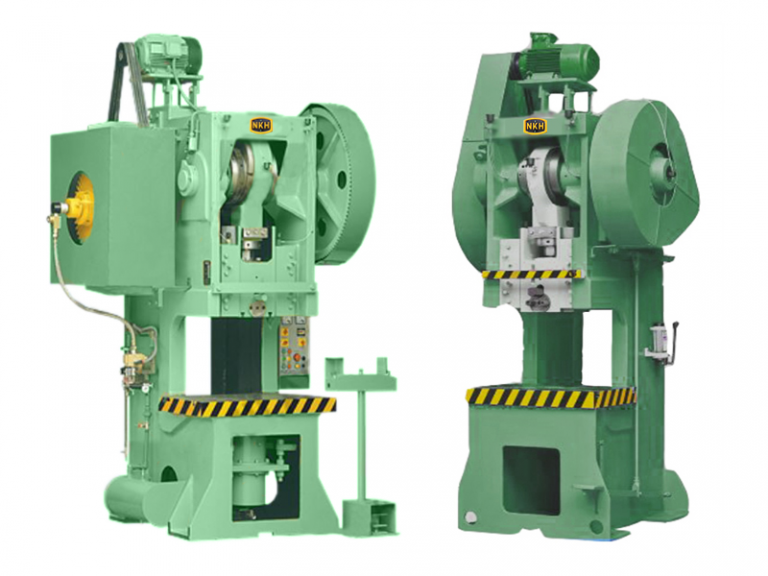

In a typical Press Machine Factory, automation plays a crucial role in streamlining the entire production workflow. From material handling and component machining to assembly, inspection, and testing, automated systems help reduce manual intervention and optimize efficiency. Advanced presses now often incorporate programmable logic controllers (PLCs), robotic feeding systems, and digital monitoring devices that allow operators to control complex processes with minimal physical input. This integration ensures consistent output quality while reducing operational risks associated with manual handling.

Automation in Material Handling

One of the earliest stages of automation in press machine factories involves material handling. Automated conveyor systems, robotic arms, and guided vehicles transport raw materials, dies, and workpieces between production stations. This reduces the need for manual labor, minimizes material damage, and ensures precise positioning for subsequent machining or pressing operations. Automated material handling also supports continuous production, which is particularly valuable in high-volume manufacturing environments.

Precision Machining and Component Fabrication

Automation significantly enhances the precision of machining operations in press machine production. CNC machines and robotic milling systems are widely used to fabricate critical components such as rams, beds, flywheels, and guide mechanisms. Automated machining ensures tight tolerances, consistent surface finishes, and high repeatability, which are essential for the reliable performance of the final press machine. Furthermore, real-time monitoring systems allow operators to detect and correct deviations instantly, reducing the likelihood of defective parts.

Automated Assembly Processes

Assembly of press machines is another area where automation plays a vital role. Robotic systems and precision jigs are used to align and fit moving components, ensuring that the ram, crankshaft, and guides operate smoothly and accurately. Automated torque control and fastening systems maintain consistent assembly quality, while sensors monitor critical parameters during assembly to prevent misalignment or mechanical stress. By automating these processes, press machine factories can reduce production time and improve the reliability of finished machines.

Integrated Safety Systems

Safety is a major benefit of automation in press machine factories. Automated systems can be equipped with sensors, interlocks, and emergency stop mechanisms to prevent accidents. Light curtains, proximity sensors, and two-hand control systems ensure that operators are protected from moving parts during operation. Automation also allows remote monitoring and control, reducing the need for personnel to be in potentially hazardous areas. These measures enhance workplace safety while maintaining production efficiency.

Quality Control and Inspection

Automation has revolutionized quality control in press machine production. Vision systems, laser scanners, and automated measuring devices can inspect components for dimensional accuracy, alignment, and surface defects. Data from these inspections can be analyzed in real time to detect trends, enabling corrective actions before defects occur. Automated testing of completed presses ensures that every machine meets operational and safety specifications, providing confidence in product quality and consistency.

Benefits of Automation in Press Machine Factories

The implementation of automation offers numerous benefits for press machine manufacturers. These include:

- Increased Productivity: Machines operate continuously with minimal downtime.

- Enhanced Precision: Automated systems maintain consistent tolerances and alignment.

- Improved Safety: Operators are less exposed to high-risk tasks.

- Reduced Labor Costs: Fewer manual interventions are required.

- Data-Driven Insights: Real-time monitoring allows for predictive maintenance and process optimization.

Future Trends

As industries adopt Industry 4.0 practices, automation in press machine factories is expected to become even more sophisticated. Integration of IoT devices, cloud-based monitoring, AI-driven predictive maintenance, and smart robotics will enable factories to achieve greater efficiency and flexibility. Manufacturers investing in advanced automation will be better positioned to meet increasing global demand for high-quality presses.

Conclusion

Automation has transformed press machine factories by enhancing precision, efficiency, safety, and quality control. From material handling and machining to assembly and testing, automated systems streamline production and reduce human error. By integrating advanced technologies, factories can produce reliable, high-performance press machines while minimizing operational risks. A modern Press Machine Factory that embraces automation ensures consistent output, improved productivity, and safer working conditions, positioning itself competitively in the evolving manufacturing industry.