The production of polyurethane (PU) foam is a complex process that requires precision, speed, and consistent quality. PU foam is widely used in automotive, furniture, construction, refrigeration, and packaging industries, making efficient manufacturing processes essential for meeting market demand. Improving production efficiency is critical for reducing costs, minimizing waste, and maximizing output, and the right PU foam machinery plays a pivotal role in achieving these goals.

Leading suppliers of PU Foam Machinery focus on integrating advanced features and technologies that enhance operational efficiency. From automated controls to high-precision metering systems, modern machinery is designed to optimize every step of the foam production process. These improvements allow manufacturers to produce high-quality foam products consistently, with faster cycle times and lower operational costs.

Automation and Smart Control Systems

One of the most significant contributors to production efficiency is automation. Modern PU foam machinery is equipped with programmable logic controllers (PLCs), touchscreen interfaces, and real-time monitoring systems. These technologies allow operators to manage chemical flow, pressure, temperature, and mixing ratios automatically, reducing human error and ensuring consistent foam quality.

Smart control systems also support predictive maintenance by continuously monitoring machine performance. Sensors detect deviations in operating conditions, triggering alerts or automatic adjustments before problems escalate. This reduces downtime caused by equipment failures and ensures that production lines remain operational without interruptions.

High-Precision Metering and Mixing

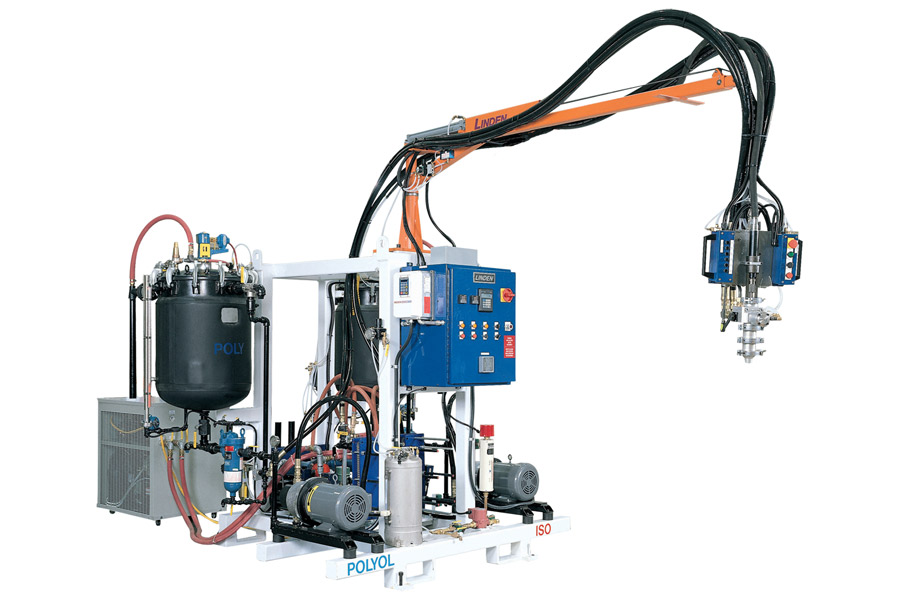

Accurate metering and mixing of polyols, isocyanates, and additives are crucial for producing consistent foam. High-precision metering pumps deliver exact quantities of chemicals, preventing overuse and reducing waste. Modern mixing heads are designed for rapid and thorough blending, ensuring uniform foam density and properties.

Improved metering and mixing systems shorten cycle times, allowing manufacturers to increase output without compromising quality. Multi-component machines with adjustable mixing ratios provide flexibility for producing different foam grades and formulations, further enhancing production efficiency.

Continuous and Batch Production Options

PU foam machinery offers both continuous and batch production modes to suit different industrial needs. Continuous production lines are ideal for high-volume operations, combining mixing, dispensing, curing, and cutting processes into a seamless workflow. These systems minimize downtime between batches and allow consistent production of foam blocks, sheets, or panels.

Batch-type machines are advantageous for specialty or custom foam products, providing precise control over each production cycle. Modern batch systems feature automated cleaning, chemical recycling, and adjustable output, reducing downtime and enabling faster changeovers between different foam formulations.

Energy Efficiency and Cost Reduction

Energy-efficient PU foam machinery contributes to production efficiency by reducing operational costs. Advanced heating systems, insulated tanks, and optimized pumps lower electricity consumption while maintaining the proper temperature and pressure for chemical reactions. Variable frequency drives (VFDs) adjust motor speeds based on demand, reducing unnecessary energy use during idle or low-load periods.

Energy-efficient designs not only cut costs but also reduce environmental impact, aligning with sustainability goals. Lower energy consumption translates into more affordable production, allowing manufacturers to improve profitability while maintaining high-quality output.

Real-Time Monitoring and Quality Control

Modern PU foam machinery incorporates real-time monitoring systems that track critical production parameters, such as temperature, pressure, flow rate, and chemical ratios. These systems enable operators to detect anomalies immediately, preventing production defects and ensuring consistent foam quality.

Integrated quality control features allow automated inspection and measurement of foam density, hardness, and expansion rate. Real-time feedback helps adjust operating conditions dynamically, minimizing rework and material wastage. This leads to higher yield rates and better utilization of raw materials.

Reduced Downtime Through Maintenance Integration

Maintenance plays a significant role in production efficiency. Many modern machines are equipped with predictive maintenance tools and automated alerts for lubrication, filter changes, or component wear. Early detection of potential issues prevents unexpected breakdowns, ensuring continuous operation and reducing costly downtime.

Modular machine designs also facilitate faster replacement of components, further minimizing interruptions. Operators can perform routine maintenance without halting production, enhancing overall productivity.

Flexibility for Diverse Foam Products

Production efficiency is closely tied to the ability to produce diverse foam products with minimal reconfiguration. Advanced PU foam machinery allows manufacturers to switch between different foam grades, densities, and shapes quickly. Adjustable output capacity, modular mixing heads, and programmable dispensing systems enable efficient production of multiple product lines without extensive downtime.

This flexibility ensures that manufacturers can meet varying customer demands while maximizing machine utilization, leading to improved overall efficiency.

Conclusion

Improvements in production efficiency with PU foam machinery are achieved through automation, high-precision metering and mixing, energy efficiency, real-time monitoring, maintenance integration, and operational flexibility. These features reduce waste, minimize downtime, and increase output, allowing manufacturers to meet growing market demands effectively.

By investing in modern PU foam machinery with advanced efficiency features, businesses can maintain consistent product quality, lower operational costs, and enhance overall competitiveness. Optimized machinery not only streamlines production but also supports sustainable and cost-effective foam manufacturing practices, ensuring long-term success in a competitive industrial landscape.